We face a global water crisis nowadays. With growing populations and industrial development, the pressure on freshwater resources has reached a critical point. One key solution lies in effectively treating and reusing wastewater. At Unistar Aquatech Private Limited, we specialize in designing and delivering efficient, sustainable, and smart water and wastewater treatment systems. Among the various treatment technologies, the wastewater treatment activated sludge process stands out as one of the most widely used and proven methods for reclaiming wastewater, especially in urban and domestic settings.

Wastewater Treatment Activated Sludge Process

The wastewater treatment activated sludge process is a biological method that uses naturally occurring microorganisms to break down organic pollutants in wastewater. Unlike purely mechanical or chemical methods, this process harnesses the power of biology to clean water in a more eco-friendly and cost-effective manner. The microorganisms, mainly bacteria, consume the organic matter in wastewater as their food source. Through this process, they convert harmful substances into harmless byproducts like carbon dioxide, water, and biomass. The result is clear, treated water that can safely be discharged or reused in gardening, irrigation, flushing, and even some industrial applications.

Historically, the activated sludge method has evolved significantly. What began as a discovery in the early 20th century is now a backbone of wastewater infrastructure in cities and towns across the world. The beauty of the activated sludge process is that it is scalable and adaptable. Whether it’s for a large municipality or a small residential complex, the system can be designed to meet the specific volume, quality, and environmental goals of the site. For instance, domestic wastewater treatment activated sludge systems are designed to cater to the needs of homes, apartments, gated communities, hotels, schools, and similar residential or semi-commercial settings. These systems are compact, highly effective, and relatively easy to maintain when properly designed and operated.

Wastewater Treatment Activated Sludge Process Diagram

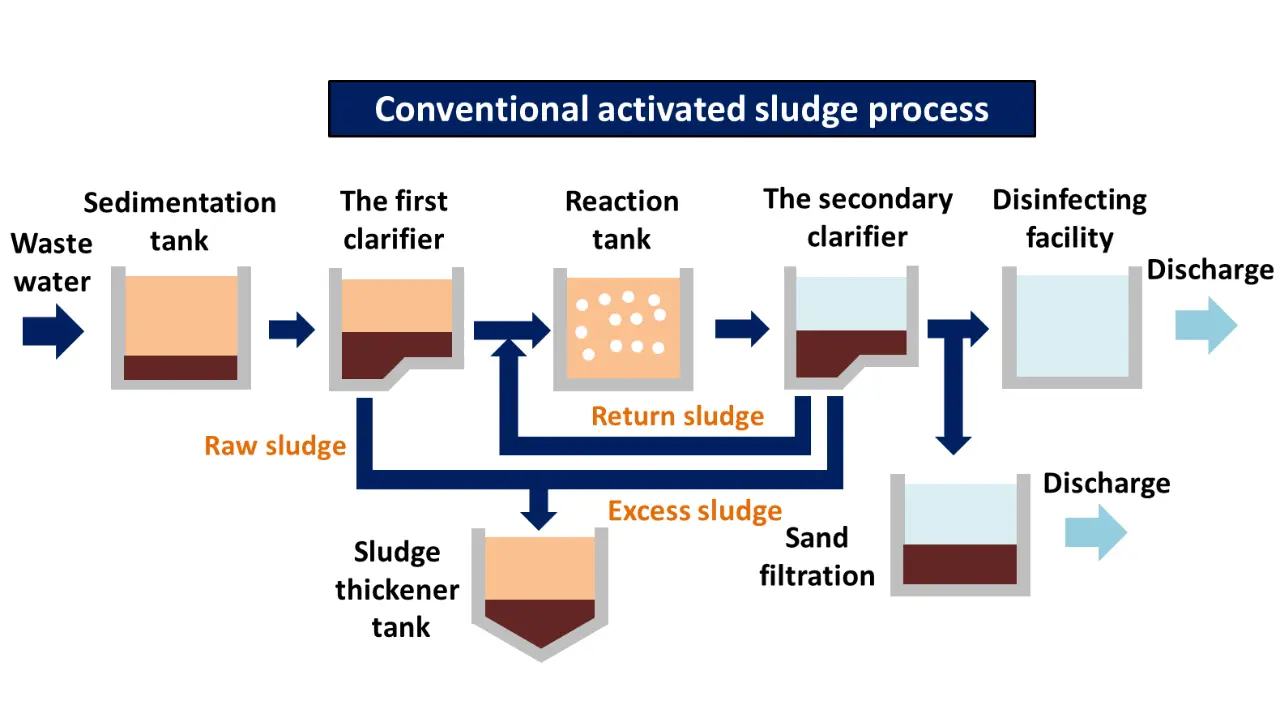

A typical wastewater treatment activated sludge process diagram consists of several key stages. It all begins with pre-treatment, where large solids, plastics, and grit are removed through screening and settling. This step is crucial to prevent damage or clogging in downstream equipment. The water then flows into a primary settling tank, where heavier organic solids settle to the bottom and lighter materials rise to the surface. From there, the partially clarified water enters the aeration tank, which is the heart of the activated sludge process.

In the aeration tank, a mixture of air and microorganisms is maintained in suspension. The air is usually supplied by blowers or diffused aerators, which keep the tank oxygen-rich and allow bacteria to thrive. These bacteria consume the organic pollutants in the wastewater, converting them into new biomass (sludge) and harmless end products. This biological treatment phase can last several hours depending on the system design and the strength of the wastewater. The water then moves into a secondary clarifier, where the newly formed sludge settles out. Most of this sludge is recycled back to the aeration tank to maintain a healthy microbial population. The excess sludge is removed and sent for further treatment or disposal. The clear, treated water is then disinfected and released for reuse or safe discharge into the environment.

While the above is a simplified version of the wastewater treatment activated sludge process diagram, the real-world implementation involves a lot of precision. Parameters like oxygen levels, microbial health, temperature, sludge age, and flow rates must be carefully monitored and controlled. This is where Unistar Aquatech brings its expertise. We design smart, sensor-enabled systems that can monitor these variables in real-time, ensuring that the treatment remains effective, compliant, and energy-efficient.

Domestic Wastewater Treatment Activated Sludge

One of the most compelling reasons to choose the activated sludge process is its proven track record in domestic wastewater treatment. Compared to other methods like septic tanks or trickling filters, the activated sludge process offers much higher efficiency in removing BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), and suspended solids. For example, in a well-designed system, over 90–95% of organic pollutants can be removed, resulting in water that’s clean enough for non-potable reuse. This is especially important in water-scarce regions, where recycling domestic wastewater can significantly reduce the demand on freshwater sources.

Another benefit of the domestic wastewater treatment activated sludge system is its modularity. The system can be customized to suit different capacities, site layouts, and performance goals. Whether you need a 10 KLD (kiloliters per day) plant for a small housing colony or a 500 KLD system for a large township, the design principles remain the same — but the scale and configuration can be adjusted. At Unistar Aquatech, we not only supply these systems but also offer turnkey solutions, including civil works, electrical integration, automation, and post-installation maintenance.

Conclusion

One concern that many clients have is about the operation and maintenance of these systems. It’s true that activated sludge plants require a basic level of attention — mainly sludge removal, aerator servicing, and occasional microbial health checks. However, with our smart automation packages, much of this can be monitored remotely. We also offer AMC (Annual Maintenance Contracts) with our systems, ensuring that clients don’t have to worry about technical upkeep. Our teams are trained to provide proactive service, system optimization, and troubleshooting when needed.

In the context of sustainability, the wastewater treatment activated sludge process aligns perfectly with global environmental goals. It promotes the reuse of water, reduces pollution load on natural water bodies, and supports decentralized water management. Moreover, some advanced versions of the process — like MBR (Membrane Bioreactor) and SBR (Sequencing Batch Reactor) — offer even higher quality output and require less physical space. These innovations are already being implemented in many of our projects at Unistar Aquatech.

One important but often overlooked benefit is the public health aspect. Poorly treated or untreated domestic wastewater is a major source of waterborne diseases such as cholera, typhoid, dysentery, and hepatitis. By ensuring effective treatment through the activated sludge process, communities can safeguard public health, improve hygiene, and even boost local biodiversity in water ecosystems.